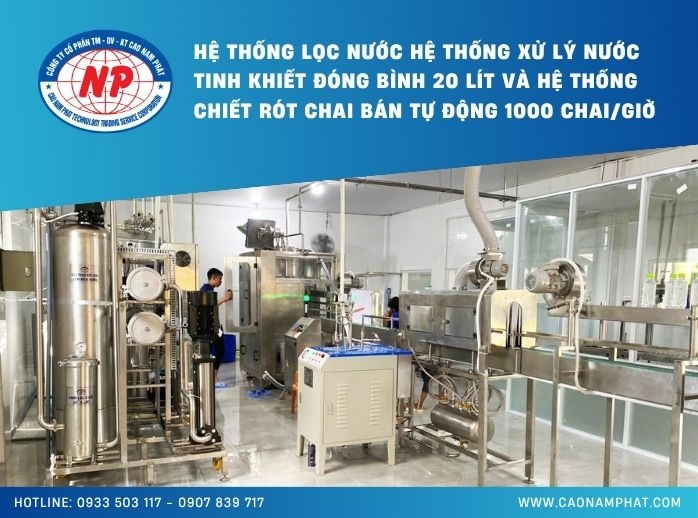

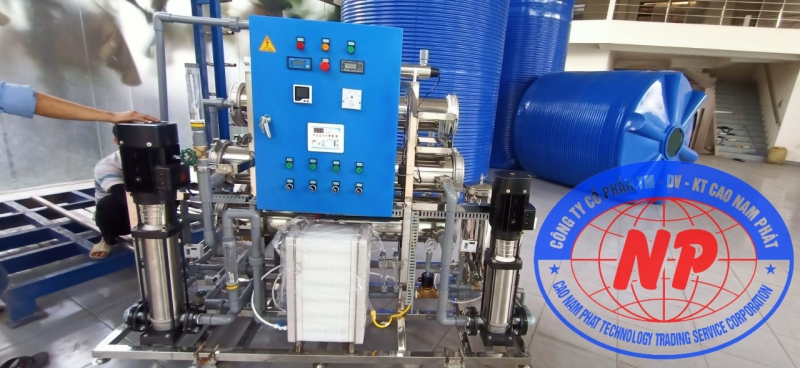

The EDI water filtration system uses advanced, modern filtration technology with a strict filtration process. The automatic system is easy to operate and costs less than other water filtration devices.

What is EDI water filtration system?

Water through EDI treatment technology used for the Medical Industry, Pharmaceutical Production and Circuit Board Manufacturing Technology is after treatment with a resistivity of up to 18.25MΩ/Cm.

.jpg)

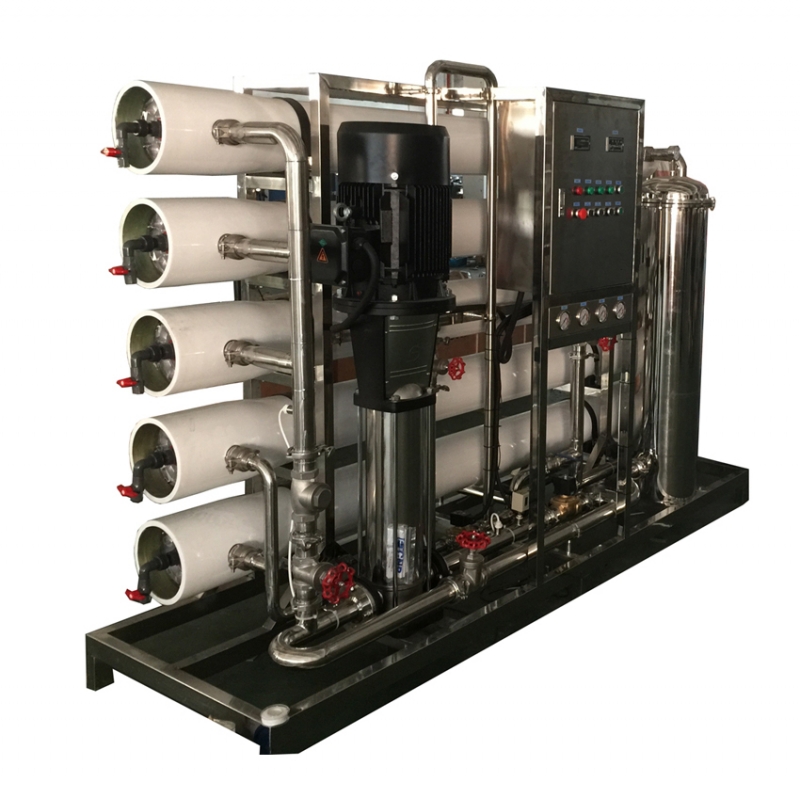

EDI water treatment system is RO – EDI (Reverse Osmosis – Electrodeionization), which is the best water filtration technology used in pharmaceutical, medical, microelectronics and food. The basic system is a combination of reverse osmosis filtration technology and demineralization of water. In a RO-EDI system, water is treated to standards through one or two RO levels and then the water is passed through an EDI demineralization device, creating ultra-pure water with a resistivity of 15-18.25. MΩ/Cm. Meets requirements in sensitive medical research laboratory applications.

For the pharmaceutical chemistry industry, the quality of water sources used for drug production for the pharmaceutical chemistry industry must ensure according to Pharmacopoeia IV standards: Electrical conductivity <4.3μS/cm, and some other indicators are not detected. Therefore, with the water production system for the pharmaceutical industry, it is necessary to apply the most advanced technology today, EDI technology.

Structure and principle of EDI water filtration system

Input source water is local water or groundwater that has been treated to meet the standards of the Ministry of Health.

The important thing in the EDI water treatment system is that in addition to demineralization, it is necessary to ensure microbiological criteria. Therefore, water tanks are made of standard SUS304 and SUS 316. The tank must always be closed during work. Gas exchange in the tank must be through an anti-bacterial air filter and devices must be installed to manage the water level in the tank to control the operation of the system.

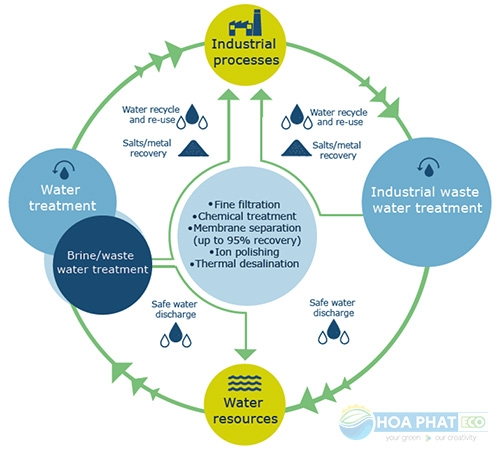

RO - EDI water treatment system has the following basic steps:

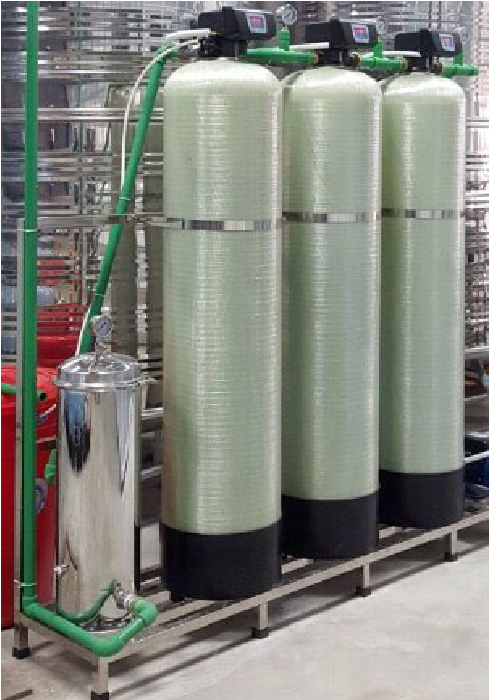

- Pretreatment System.

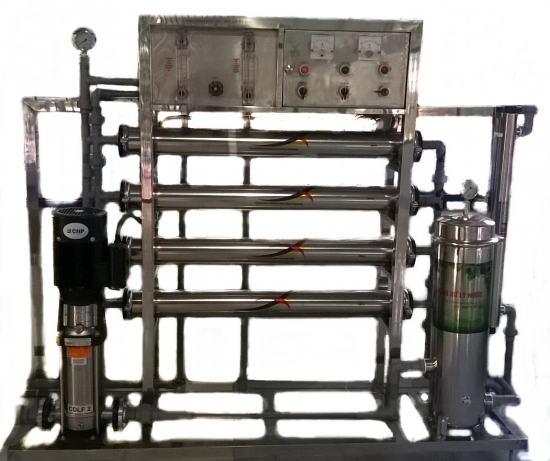

- RO reverse osmosis filtration system (RO System)

- EDI demineralization system (EDI System).

- Sterilization System.

- Water treatment process using EDI technology

Step 1: Multi-function crude filter device: the water source for the EDI system is usually taken from tap water systems or underground water that meets standards. Multi-function coarse filter equipment: Main materials are quartz sand, Manganese particles, Multi-purpose filter particles,... removes suspended, large-sized residues in water, absorbs metal ions on the surface of the material, Thoroughly treat metal ions in water.

Step 2: Equipment to remove residual chlorine and taste in water: main material is Activated Carbon. Effective in removing organic compounds, deodorizing, taste and removing excess chlorine in water.

Step 3: Ion exchange filter device to remove hard water: the main material is ion exchange resin: it has the effect of removing metal cations and anions in water, reducing water hardness.

Step 4: Cartridge: the main material is the BDM filter core with a size of less than 5µm, which helps remove suspended solids in water before entering the RO reverse treatment system.

Step 5: Reverse osmosis filtration equipment: Reverse osmosis filtration system with RO membrane has water filtration efficiency up to 96.95%, completely removing foreign ions, bacteria, fungi, algae... output water Meets pure water requirements, conductivity below 10µS/cm.

Step 6: EDI demineralization device: water after going through the RO filtration system meets pure water requirements, achieving conductivity below 10µS/cm. Then, the water is passed through the EDI (Electrodeionization) demineralization device, which is a continuous process, which is a combination of two processes: deionization by ion exchange and electrofilation. After going through the EDI device, it continuously creates ultra-pure water with a resistivity of up to 18.25MΩ·cm. Meets standards for applications in industries requiring extremely low conductivity and extremely high resistivity such as: Microelectronics, microchips, power generation, Healthcare and Pharmaceuticals.

Step 7: Sterilization equipment: After the water source goes through a standard treatment system, it continues through a sterilization equipment that can be performed with ultraviolet rays or ozone, helping to kill bacteria. It is then passed through a microbial sterilization filter before being put into a container for use.

EDI water filtration system operates fully automatically:

- Use online conductivity measuring devices, set application standards to control system operations via PLC programming software.

- The system operates automatically, strictly controls water quality, and provides timely warnings

- To achieve ultra-pure water quality and meet production needs, after 2-level RO, the water is demineralized using EDI equipment.

To know more about the technology that suits your needs, please contact us for advice:

Hotline/Zalo: 0933 503 117 (Water purifier customer service)

Hotline/Zalo: 0907 839 717 (Project/Treatment system)

CANAPHACORP - The Best ultra Pure Water Filter in Vietnam